After a longer, Covid-19-related break, Rotzinger PharmaPack was represented for the first time with its own booth at Achema from August 22 to 26 this year. Under the motto “sustainable and innovative packaging solutions for your needs”, visitors were able to experience an overview of the Rotzinger Pharma portfolio. Among the products on display at the booth were two production lines, one for filling and capping bottles and other containers, and another for cartoning plus a track & trace solution.

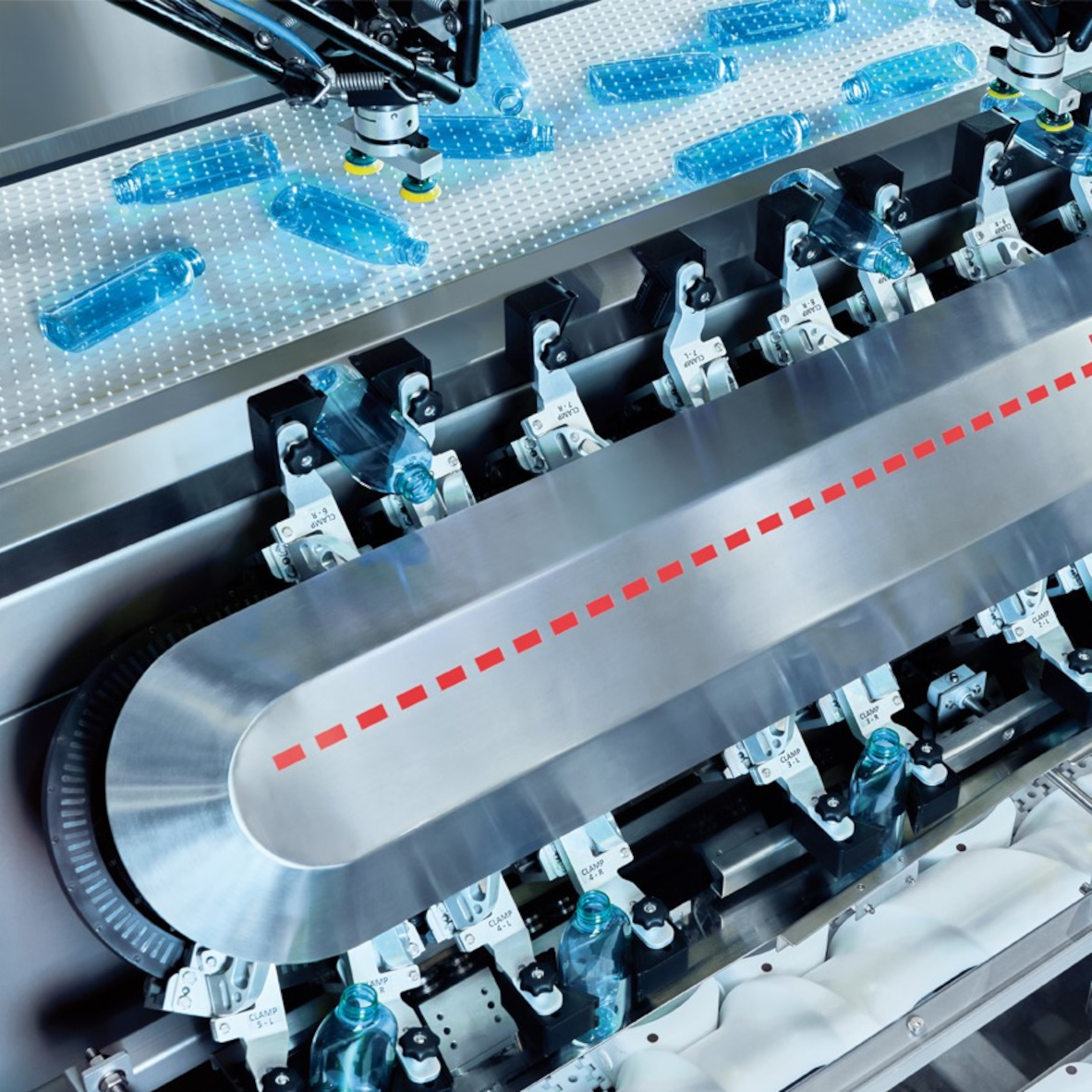

The filling and capping line consisted of a Pickfeeder and an FLK series linear filling and capping machine. The Pickfeeder unscrambles bottles and aligns them. The pickfeeder does this highly efficiently using pick-and-place robot technology. The pickfeeder then transfers the containers to the downstream machine where, in the case of the trade show exhibit, they are filled and capped in a continuous process.

An intermittently operating line for cartoning syringes was the second solution exhibited at Achema. Within this line, the syringes are placed in the inlay by a pick & place robot and then pushed into the carton together with a booklet. Instead of a booklet, an instruction leaflet can of course also be enclosed. The line was supplemented by a compact and flexible track & trace solution for product serialization.

The exhibited cartoning line is also the optimal solution for sustainable and sustainably produced packaging such as the Eco Save Pack. This was developed in cooperation with Faller Packaging especially for fragile products. It is a folding tray carton whose inlays are specifically adapted to the respective contents. All packaging components are made of environmentally friendly cardboard material. With their chamber design, the inlays also provide optimum protection for syringes, vials or ampoules, among other things, during storage and transport.

Other highlights were the Wyzo and the Digital Factory. The Wyzo is the world’s first high-speed pick & place sidebot that can work side by side with human members of a production team. The Digital Factory (DF4) is a manufacturing execution system (MES) developed within the Rotzinger Group. It is offered in a version designed specifically for the needs of the pharmaceutical industry.