Carton erecting, conveying, filling, closing and, if desired, printing. We have combined these processes in a single machine. Its name: Hector. Its area of application: cartoning of primary packaged products. Its core competencies: it is compact, versatile, efficient and reliable. And what does that mean exactly?

Compact

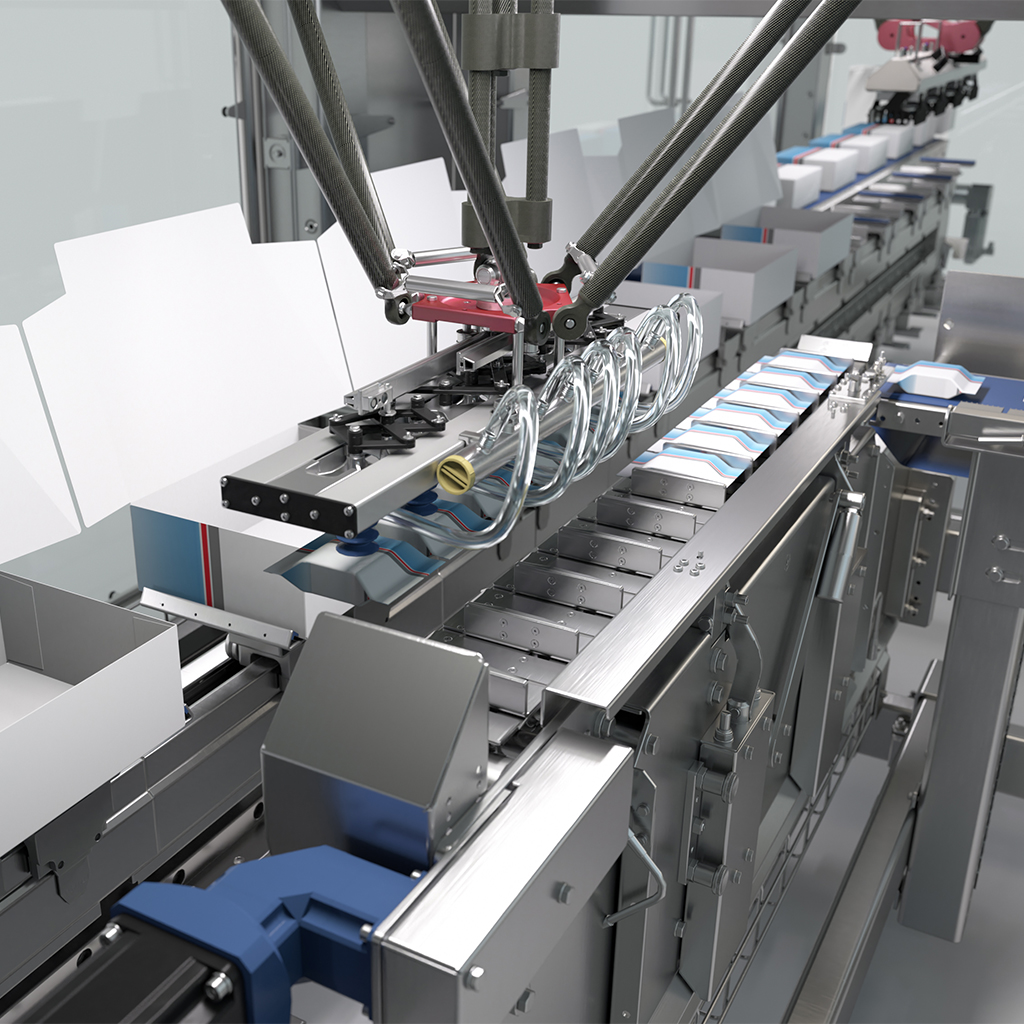

The integration of carton former, robotic cell and carton closer into a single machine eliminates the need for mechanical interfaces. Compared to solutions with separate individual components, Hector requires only about half the floor space. Of course, an additional printer unit for printing the cartons can also be integrated.

Flexible

Hector is an optimal choice for an enormous number of applications. As long as the individual sides of the boxes are rectangular and the maximum edge length is not exceeded, the box conveyor is not subject to any further restrictions in terms of geometry. The specific dimensions can be conveniently defined via the HMI. In addition, format changes can be carried out quickly. A complete format change is executed by one person in just ten minutes. In addition, the same tool can be used for carton closing if only the height of the box changes.

Efficient

Hector can process up to 150 boxes per minute with high energy efficiency. The machine is designed as a toploader. This makes the process more cost-effective than sideloading. Jobs requiring a smaller number of boxes per minute can be processed with a smaller number of closing tools. The box conveyor, in turn, does not require any shape-specific tools at all. Both features reduce tooling costs.

Reliable

Our subsidiary Demaurex is a robotics pioneer. The robotic cell has been matured to perfection. Together with carton erector and carton closer, it forms a fully integrated, reliable solution for cartoning. Delta robots from Demaurex are capable of handling any common type of initial packaging. This is also ensured by the self-developed and first-class vision system with the quality inspection working at a high level. Of course, we guarantee the perfect squareness of the boxes produced and, thanks to the vacuum check, we ensure that every single box has been filled correctly. Optionally, Hector can be equipped with a control system that checks whether each box has been closed correctly.