Food & Confectionery

Pharma

Cosmetics

More Industries

Services

Careers

Company

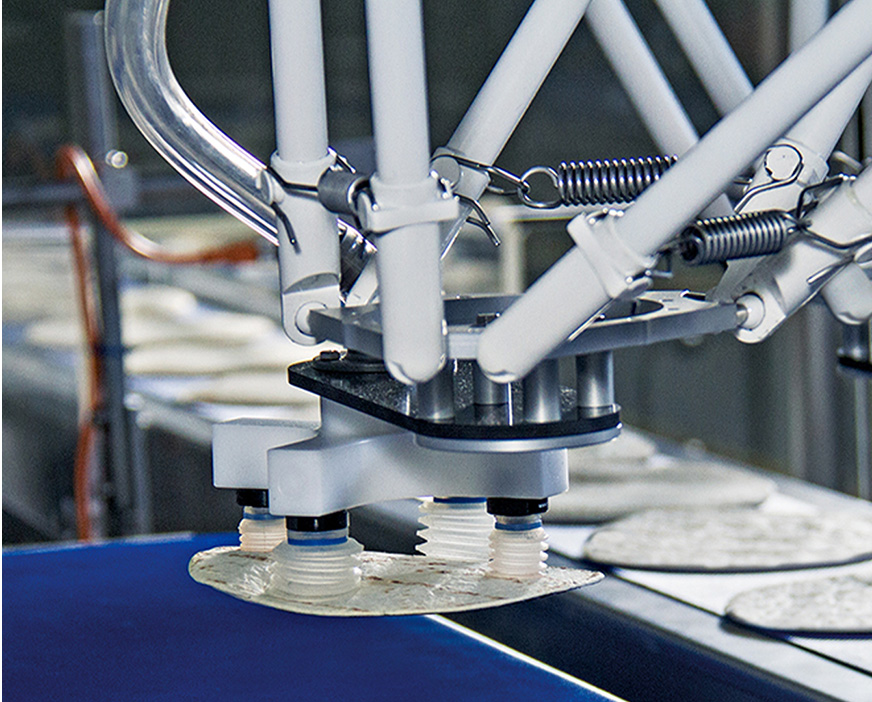

Food & Confectionery

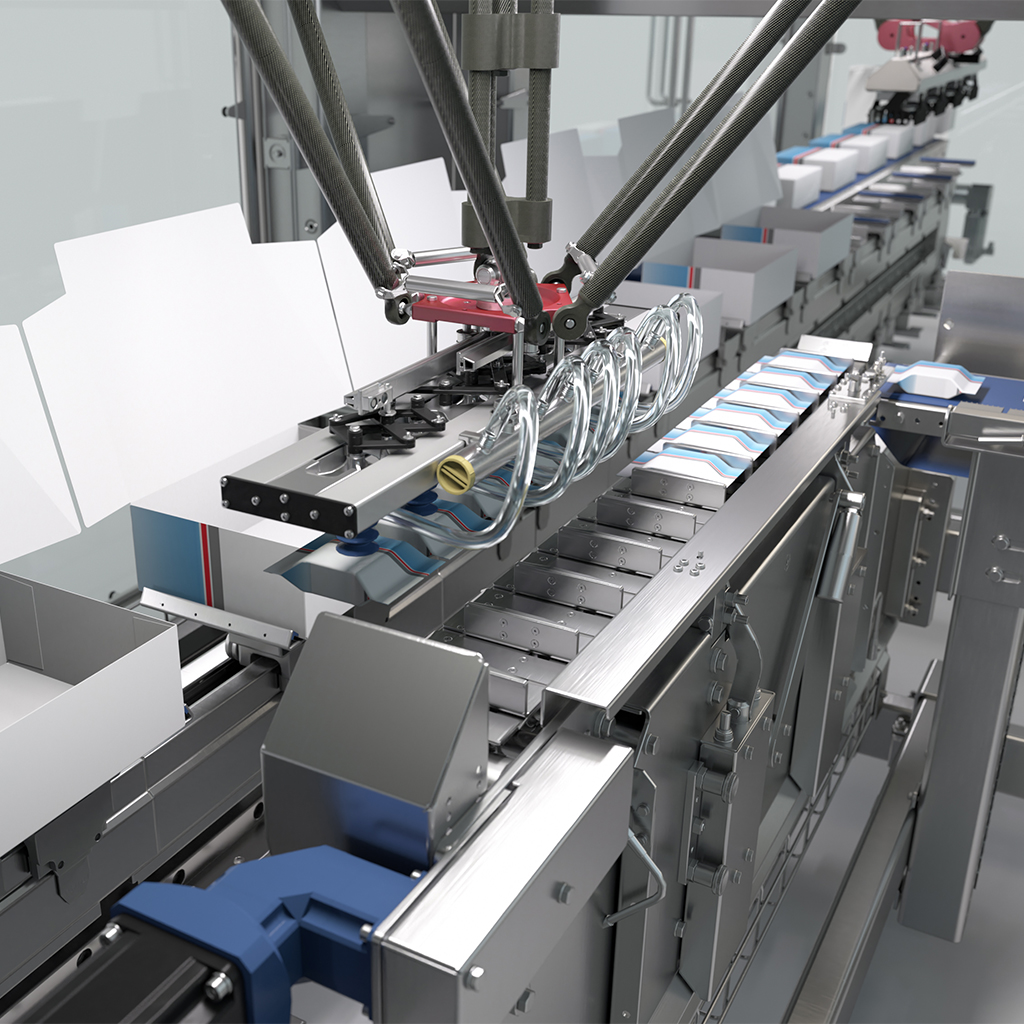

Pharma

Cosmetics

More Industries

Services

Company